Heat exchangers: production of heat exchange equipment

-

Place an order

Place an orderHeat exchangers of the “Pipe in a pipe” type

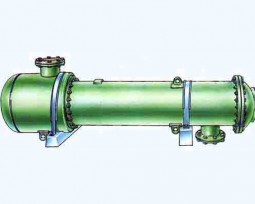

Heat exchangers are designed for heating and cooling media in the technological processes of petroleum, chemical, petrochemical, gas and other industries. Heat exchangers are

-

Place an order

Place an orderThe devices are designed for heat exchange of liquid and gaseous media in technological processes of chemical, petrochemical, oil refining, oil, gas and other industries. Heat

-

Place an order

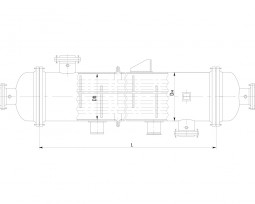

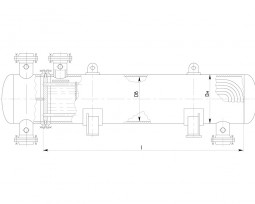

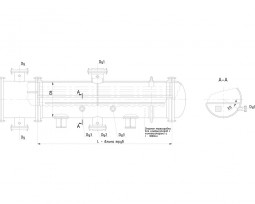

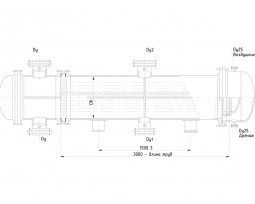

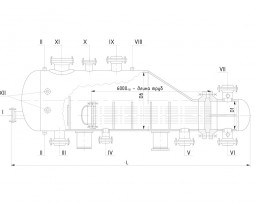

Place an orderShell-and-tube heat exchangers

What is a shell-and-tube heat exchanger? This is an aggregate designed for temperature exchange between cold and hot autonomous flow due to the movement of liquids in different

-

Place an order

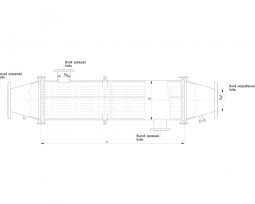

Place an orderSteam-water and water-water heaters for heating and hot water supply networks

Heaters are designed for heating water in heating and hot water supply systems of residential, public and industrial buildings. The devices can be operated in macroclimatic

-

Place an order

Place an orderCondensers are designed for condensing media under vacuum in the technological processes of petroleum, chemical, petrochemical, gas and other industries. Vacuum condensers with

-

Place an order

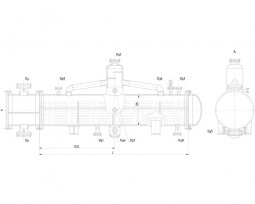

Place an orderFlash exchangers are designed for the evaporation of media in the technological processes of petroleum, chemical, petrochemical, gas and other industries. Thermosiphon

-

Place an order

Place an orderFlash exchangers with steam space and tube bundles to them

These devices are designed for evaporation of technological media in the processes of petroleum, chemical, petrochemical, gas and other industries. The devices are manufactured

-

Place an order

Place an orderRefrigerant flash exchangers and capacitors

The evaporators are designed for cooling water, solutions and liquid process media flowing through the pipes of the units with ammonia, propane, propylene and other refrigerants

-

Place an order

Place an orderAftercoolers for stationary reciprocating opposed general purpose compressors with a capacity of 50 m³/min (HK-50), 100 m³/min (HK-100) are designed to cool the air sent to the

Applications for heat exchangers

Scopes of heat exchangers are diverse. The most popular are the following:

Scopes of heat exchangers are diverse. The most popular are the following:

- heating and hot water supply systems, in public utilities and in production,

- in heavy industry and mechanical engineering in systems for heat removal from the working area and vice versa, etc.,

- in the chemical industry - to create the necessary temperature during chemical reactions,

- in agriculture - used in the pasteurization of milk, butter, beer, juices,

- on ships - for desalination of sea water.

Types of heat exchangers for use

The design of the device depends on the operating conditions. In addition to its main function, heat exchangers can also perform related processes: evaporation, mixing, condensation, phase transformations. In their design, the main are two types of heat exchangers:- shell-and-tube - consists of a large number of tubes through which the coolant circulates, the role of which, in most cases, is hot water. Heat exchange with the surrounding space occurs through the surface of the casing. Among the disadvantages are low heat transfer coefficients and a large heat transfer surface.

- lamellar - has a large external area, and instead of tubes here flat plates are used. Inside the plates there are divided channels that exchange heat.

Types of shell-and-tube and plate heat exchangers

Shell-and-tube heat exchangers can be of the following types:- classic, when a group of pipes for one coolant is inside the casing along which another coolant moves,

- "pipe in pipe" - inside one conductive pipe is another. This design is the simplest and cheapest, but it has a low heat transfer efficiency,

- helicoid - in this design, profiled pipes and helicoid ribs are used, with the help of which swirl flows are created inside the pipes, which improve the heat transfer conditions.

- collapsible - consist of a set of heat transfer plates with polymer gaskets that create closed channels for heat-conducting media. Heat transfer efficiency is high,

- soldered - in them plates are assembled in a sealed case, in which they are sealed with soldered seams, form a honeycomb structure with separate channels for circulation of both heat carriers. They have a wider range of operating temperatures and pressures.

- welded/shell-plate - they have the same principle of operation as brazed heat exchangers, but they are used for large thermal capacities, pressures and temperatures.

- spiral, when spiral rectangular channels for the movement of media are formed by large steel sheets welded to the central manifold and curled around it in a spiral

- submersible - the heated coil tube is lowered into an open container with refrigerant,

- irrigated - the pipe system is irrigated by jets of liquid that flows freely,

- duct heaters that are blown by a stream of air.

- carbon steel,

- stainless steel,

- aluminum,

- special heat-resistant or cold-resistant alloys,

- titanium,

- graphite.

Specifications

The main parameter of the heat exchanger is its power, which depends on the heat transfer index, the heat transfer area and the temperature difference between the heat carriers. No less important parameters are the following characteristics of heat exchangers:- difference in input temperatures of coolants,

- working and maximum heat carrier pressure,

- working and maximum temperature,

- flow rate of the heat carrier through the heat exchanger,

- inlet temperature difference,

- degree of chemical resistance of the heat exchanger (corrosion),

- gas-dynamic resistance,

- dimensions and weight,

- having access to service and repair the device.

Principle of operation of the heat exchanger

Heat exchangers can operate in three main processes: convection, thermal radiation, and thermal conductivity. Heat can be supplied to a cold object in several ways: mixing and heat transfer. For example, the mixing method combines the interaction of air and liquid. As a result, you can get high performance, which can only be achieved by mixing two media. Each heat exchanger has a set of devices that work according to a special principle:- recuperative (using two different liquids),

- regenerative (the presence of an element that is both a source of supplied heat and a charger).

Benefits of heat exchangers

By purchasing heat exchangers even for small production, you can get the following benefits:

By purchasing heat exchangers even for small production, you can get the following benefits:

- cut production costs,

- increase production efficiency,

- save production space, as the equipment takes up little space,

- due to the high turbulent flow, the self-cleaning effect is achieved, so you do not need to resort to frequent maintenance of the apparatus, etc.

Heat exchangers and their maintenance

When operating heat exchangers, it is necessary to regularly monitor the stability of the heat exchangers. Changing temperature parameters may indicate that the efficiency of the equipment is reduced. In this case, it is necessary to check the condition of the heat exchange surfaces, as salts may precipitate on them. For their cleaning, an ultrasonic method of protecting pipes and channels of heat exchangers is used - this allows to reduce the rate of scale formation or to ensure the operation of the apparatus without the formation of deposits. Another type of work that must be performed when servicing the apparatus is cleaning external units that come in contact with atmospheric air. The external unit can become clogged with dust, leaves and other debris, because of which it stops passing air, the compressor starts to overheat, which can lead to the failure of the heat exchanger. In order to prevent this from happening, a routine inspection of the heat exchanger must be arranged at least once a year. With regular maintenance, the equipment can last at least 18-20 years without repair.Heat exchanger manufacturing process

The production of heat exchangers is a process of assembling several components that are selected individually:- frame size,

- number of plates/tubes for heat transfer,

- type of sealing material.

- maximum heat load,

- media between which heat exchange will take place

- temperature of the medium at the inlet and outlet of the heat exchanger.

How to choose a heat exchanger?

When choosing a heat exchanger, you can rely on the functions that the equipment has and on the technical characteristics. By function:- heating medium in heating and domestic hot water: steam and water,

- heating fuel oil during oil refining,

- oil cooling: oil coolers MO, MB,

- food cooling,

- Coolant cooling for marine engines: OB diesel coolers,

- condensation of steam deaerators of thermal points: evaporators coolers OVA, OVV.

- heat transfer surface area,

- heat transfer medium parameters,

- hydraulic resistance,

- nominal flow rate, etc.

Expert recommendations

The design of each heat exchanger is unique, they have a complex structure, so we recommend that you listen to the recommendations of specialists:- The main advice on the use of heat exchangers is regular maintenance of the device and its repair,

- experts do not recommend creating heat exchangers at home, because this process is designed for production installation.