Shell-and-tube heat exchangers

What is a shell-and-tube heat exchanger? This is an aggregate designed for temperature exchange between cold and hot autonomous flow due to the movement of liquids in different cavities. The equipment is widely used in thermal power plants, the oil industry, as well as in the food and chemical industries. The devices are famous for their reliable design, excellent functionality and high efficiency of heat transfer. They are used as condensers, heaters and evaporators.

JSC “Teplokhim” is engaged in the production and sale of various equipment, including shell-and-tube heat exchangers. Here you can buy high quality devices at loyal prices!

The device and principle of operation of shell-and-tube heat exchangers

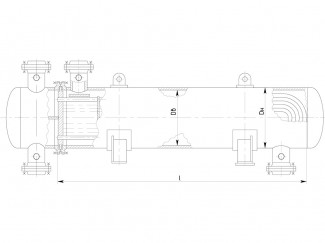

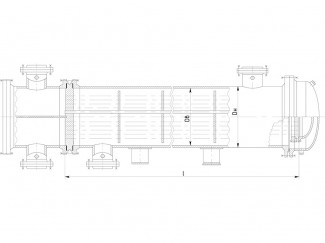

The design of shell-and-tube heat exchangers is presented in the form of tube bundles fixed with gratings, a spherical or flat bottom, a cylindrical casing, a distribution chamber and a condensate outlet. Pipes with a diameter of 12 to 57 mm can be placed vertically or horizontally.

The principle of operation of the unit is to transfer heat through different channels located between the coolants. Shell and tube heat exchangers are a simple cylindrical device, due to which they can be easily assembled and disassembled, as well as preventive cleaning. Energy carriers can be in different states of aggregation – gaseous, vaporous or liquid. Due to the modeling and operation of the equipment, a large heat exchange area with a small unit size, high mechanical strength and reduced resource consumption are ensured.

Calculation and design of a shell-and-tube heat exchanger

Sometimes, to meet the needs of the process chain, it is necessary to carry out detailed calculations of the design of the shell and tube heat exchanger. Many values need to be known to use the equations: inlet/outlet temperature, LMTD, heat transfer area and rate, and overall coefficient.

Sometimes, to meet the needs of the process chain, it is necessary to carry out detailed calculations of the design of the shell and tube heat exchanger. Many values need to be known to use the equations: inlet/outlet temperature, LMTD, heat transfer area and rate, and overall coefficient.

The design of shell and tube heat exchangers is most often carried out using software to create a model of the device, which is then used to simulate the operation of the heat exchanger and verify that it meets certain process requirements. The specialists of Teplokhim JSC, who carry out the calculation and design of shell-and-tube heat exchangers, have extensive experience and professionalism, which makes it possible to avoid the likelihood of any errors and shortcomings.

Advantages of shell and tube heat exchangers

Shell and tube heat exchangers offer a number of advantages:

- long service life;

- wear resistance;

- suitability for repair;

- the ability to work in an aggressive environment;

- increased resistance to water hammer;

- the possibility of interaction with contaminated substances and low-quality liquids;

- ease of maintenance and mechanical cleaning.

Disadvantages and difficulties when working with shell-and-tube heat exchangers

Although the design of shell-and-tube heat exchangers has a significant number of advantages and advantages, the apparatus still has some disadvantages. Among them:

- high complexity of design and manufacture;

- significant weight and overall dimensions of the device, which is why for its placement it is necessary to select a room with a large area;

- low efficiency compared to a plate heat exchanger;

- dependence of heat transfer on the velocity of the fluid;

- high price due to high metal content (up to 60%).

Specifications of shell and tube heat exchanger

According to the technical characteristics, the device of shell-and-tube heat exchangers can be of various designs:

According to the technical characteristics, the device of shell-and-tube heat exchangers can be of various designs:

- rigid, semi-rigid and non-rigid;

- single-way, multi-way and vertical;

- inclined or horizontal;

- direct-flow, cross-flow or counter-current, depending on the type of CSF movement.

The temperature of the heat exchange media inside the unit ranges from -70 to 350 degrees. The value of the minimum heat exchange surface area is less than 1 square meter. Depending on the structure, the diameter of the casing is 400-1200 mm. The length of the pipes should be 1.5-9 m, which is affected by the diameter of the installation.

Types and types of shell-and-tube heat exchangers

Devices of shell-and-tube heat exchangers are usually classified depending on the direction of the coolant. Among them: direct-flow, cross-flow and counter-flow.

According to the value of the movement of the speed of the substance and the heat transfer coefficient, heat exchangers are divided into the following types:

- with fixed tubes;

- floating head;

- with temperature casing compensator;

- with U-tubes.

Among the types of shell-and-tube heat exchangers, there are designs of TP, TPK, TK, TN, TU, TU.

Shell and tube heat exchangers with compensator

During the operation of heat exchange equipment, various difficulties may arise. To avoid this, a special design of the shell-and-tube heat exchanger was created, which was equipped with a lens compensator. This installation allows you to reduce the temperature at the joints of tube sheets, pipes and casing.

During the operation of heat exchange equipment, various difficulties may arise. To avoid this, a special design of the shell-and-tube heat exchanger was created, which was equipped with a lens compensator. This installation allows you to reduce the temperature at the joints of tube sheets, pipes and casing.

TPK – shell-and-tube heat exchangers with a floating head and a compensator

Shell and tube heat exchangers of this type are hybrids of TP and TC types. Such devices are characterized by a simple design, which significantly increases the final cost of the product. The main advantage of shell-and-tube heat exchangers with a floating head with a compensator is a significant degree of stability when operating under conditions of high pressure and temperature increase. Due to this, the equipment can be used for heating or cooling liquid and gaseous substances.

Where are shell and tube heat exchangers used?

Shell and tube heat exchangers are commonly used in various fields. In housing and communal services, they are used to supply hot water to a residential building. In industry, heat exchangers are used in the oil, chemical and gas industries. This device is most in demand as heat recovery units, condensers and heaters.

Repair of shell-and-tube heat exchangers in Teplokhim JSC

In order for the shell-and-tube heat exchanger to serve the production for many years, we recommend that you follow certain rules for their operation and carry out scheduled maintenance, cleaning the tubes of the unit from various sediments and blockages. If the device still becomes unusable, it should be repaired or replaced with new equipment.

Competent specialists at Teplokhim JSC will conduct an initial diagnostic of the product, which will determine the main problems and the amount of work to be done.

Place an orderОсновные типы и технические характеристики теплообменников кожухотрубных

| Наименование, ТУ, код ОКП | Краткая характеристика | ||||||

| Диаметр кожуха, мм, DH , DB | Длина труб,мм, ℓ | Сортаменттруб, мм | Числоходов по трубам | Условное давление, МПа | Площадь поверхности теплообмена, м2 | ||

| в кожухе | в трубах | ||||||

| Теплообменники с плавающей головкой (ТП) ТУ 3612-023-00220302-01 ОКП 361212 | 325 | 2 | 2,5; 4,0 | 10,4 – 26,4 | |||

| 400* | 3000; 6000 | 2,5; 4,0; 6,3 | 19,3 – 46,7 | ||||

| 500* | 2,5; 4,0; 6,3; 8,0 | 31,1 – 77,6 | |||||

| 600* | 6000 | 2; 4 | 1,6; 2,5; 4,0; 6,3; 8,0 | 85,7 – 130,4 | |||

| 700* | 118,7 – 171,8 | ||||||

| 800 | 163,0 – 377,6 | ||||||

| 900 | 6000; 9000 | 1,6; 2,5; 4,0; 6,3 | 210,1 – 486,1 | ||||

| 1000 | 268,9 – 608,2 | ||||||

| 1200 | 409,8 – 914,5 | ||||||

| Холодильники с плавающей головкой (ХП)ТУ 3612-023-00220302-01ОКП 36 1212 | 325 | 2 | 4,0; 6,3 | 1,0 | 10,4 – 26,4 | ||

| 400* | 3000; 6000 | 19,3 – 46,7 | |||||

| 500* | 31,1 – 77,6 | ||||||

| 600* | 6000 | 20×2; | 2; 4 | 2,5; 4,0; 6,3 | 85,7 – 130,4 | ||

| 700* | 118,7 – 171,8 | ||||||

| 800 | 25×2; | 163,0 – 377,6 | |||||

| 900 | 6000; 9000 | 1,6; 2,5; | 210,1 – 486,1 | ||||

| 1000 | 25×2,5 | 4,0; 6,3 | 268,9 – 608,2 | ||||

| 1200 | 409,8 – 914,5 | ||||||

| Конденсаторы с плавающей головкой (КП)ТУ 3612-023-00220302-01 ОКП 36 1212 | 600* | 6000 | 2; 4; 6 | 1,0; 1,6; 2,5 | 1,0 | 83,4 – 130,4 | |

| 700* | 120,1 – 187,6 | ||||||

| 800 | 169,1 – 251,7 | ||||||

| 900 | 224,7 – 324,0 | ||||||

| 1000 | 293,9 – 405,4 | ||||||

| 1200 | 441,3 – 609,7 | ||||||

| Теплообменники с U – образными трубами (ТУ)ТУ 3612-023-00220302-01ОКП 36 1213 | 325 | 2 | 2,5; 4,0 | 12,1 – 32,2 | |||

| 400* | 3000; 6000 | 2,5; 4,0; 6,3 | 23,0 – 61,6 | ||||

| 500* | 41,7 – 101,3 | ||||||

| 600* | 6000 | 1,6; 2,5; 4,0; 6,3 | 115,5 – 144,4 | ||||

| 700* | 160,0 – 202,0 | ||||||

| 800 | 212,5 – 406,4 | ||||||

| 900 | 1,6; 2,5; 4,0 | 286,9 – 522,9 | |||||

| 1000 | 6000; 9000 | 354,2 – 664,0 | |||||

| 1200 | 1,6; 2,5 | 554,5 – 974,4 | |||||

| 1400 | 758,8 – 1369,7 | ||||||

Допускается изготавливать кожух аппаратов из труб наружным диаметром 426, 530, 630, 720 мм.

Если вам требуются теплообменники кожухотрубные, компания АО «Теплохим» готова спроектировать для вас индивидуальное решение с требуемыми для вашего производства параметрами.