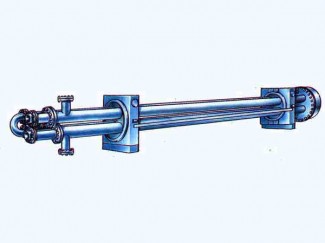

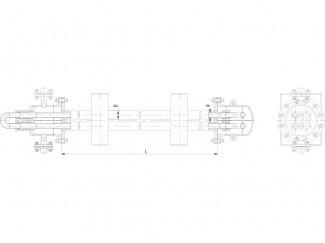

Heat exchangers of the “Pipe in a pipe” type

Heat exchangers are designed for heating and cooling media in the technological processes of petroleum, chemical, petrochemical, gas and other industries.

Heat exchangers are manufactured in the following versions:

- welded twins;

- with removable twins.

In heat exchangers, smooth heat exchange pipes (G) are used. Supplied with mating flanges, fasteners and gaskets.

Heat exchangers can be operated in macroclimatic regions with temperate and tropical climates. Climatic version “U” and “T”, product category 1, 2 and 3 according to GOST 15150-69.

Heat exchangers are designed for installation in geographic areas with seismicity less than 7 points according to the 12-point scale adopted in the Russian Federation. The possibility of operation in areas with a seismicity of 7 or more points is determined by the calculation for seismicity according to SNiP II -7-81 (taking into account the specific size and layout of the devices).

When ordering heat exchangers, a questionnaire is provided.

When ordering heat exchangers with design changes provided for by TU 3612-014-00220303-99, an order form is provided.

Limits of application in terms of temperature in the pipe and annulus space from minus 30°C to 400°C for apparatuses of the TTOR, TTM, TTRM types from minus 30°C to 300°C for apparatuses of the TTON type.

The main materials used in the manufacture of devices: carbon steel, stainless steel.

Recommendations for the selection and scope of heat exchangers of the “pipe in pipe” type.

Heat exchangers type TTRM.

Collapsible low-flow tube-in-tube heat exchangers TTRM are designed for relatively low flow rates of working media.

Low-flow heat exchangers can be used for laboratory and pilot plants, as well as oil heaters and oil coolers in various industries.

Single-flow heat exchangers (TTRM1), in which the medium makes 4 passes through the pipe and annular spaces, are designed for convective heat transfer processes.

Double-flow heat exchangers (TTRM2), in which the medium makes 2 passes, can also be used for processes with condensation and evaporation in tube and annular spaces.

Single-flow devices in the tube space and double-flow devices in the annular space (TTRM 1/2) are used in cases where convective heat exchange takes place inside the heat exchange pipes, and outside the process with condensation and evaporation, for example, as a steam heater for a liquid product.

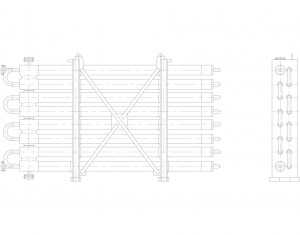

Heat exchangers type TTM.

Collapsible multi-flow tube-in-tube heat exchangers TTM, in contrast to single-flow ones, are designed for relatively high flow rates of working media. TTM5, TTM7, TTM12, TTM22, TM31 are manufactured.

Multiflow heat exchangers can be used for convective heat exchange processes “liquid-liquid”, “gas-gas” and “liquid-gas”, as well as for heat exchange processes with partial condensation or evaporation of working media.

The design of multi-flow collapsible heat exchangers provides for the possibility of thermal elongation of heat exchange tubes. The possibility of thermal elongation of shell pipes is limited by the design, therefore, the temperature difference between the inlet and outlet of the medium passing through the annular space of one apparatus should not exceed 150 ° C.

The design of collapsible multi-flow heat exchangers provides the possibility of extracting heat exchange pipes for their replacement or mechanical cleaning of the outer surface from contamination.

If it is necessary to regularly mechanically clean the inner surface of the heat exchange tubes (without removal), devices with removable twins on the heat exchange tubes are selected, that is, devices of execution 2 and, consequently, smaller sizes (ТТМ5, ТТМ7).

Heat exchangers TTOR.

Gasketed single-flow tube-in-tube heat exchangers TTOR are designed for contaminated and prone to significant deposits of working media, as well as for media carrying suspensions, that is, for such technological conditions when separation of the working medium into parallel flows is not allowed.

The devices are designed for use in various treatment plants built for the purpose of environmental protection, including sewage sludge treatment plants, oil sludge incinerators and similar operating conditions in other industries with liquid flow rates in the annular and pipe spaces from 2 to 60 t/h

The design of the devices provides the possibility of regular mechanical cleaning of the inner surface of the heat exchange tubes from contamination, as well as the possibility of excavating the heat exchange tubes for their replacement or mechanical cleaning of the outer surface.

A more polluted medium passes in one stream inside the heat exchange tubes, while making four passes through the tube space. The less polluted medium flows countercurrently outside the heat exchange tubes, also making four passes along the annulus.

It is allowed to make the device two-way and, therefore, two-flow along the annular space for those cases when it is due to the conditions of heat exchange (outside the heat exchange tubes – the process of heat exchange with evaporation or condensation). For example, when using the device as a steam heater of a contaminated product.

by design devices, the possibility of free temperature extensions of heat exchange tubes is provided. The possibility of thermal elongation of casing tubes by the design of single-flow four-passage devices along the annular space is limited, therefore, the temperature difference between the inlet and outlet of the medium passing through the annular space of the apparatus should not exceed 150°C.

Heat exchangers type TTON.

Non-separable single-flow tube-in-tube TTOH heat exchangers are designed for such operating conditions when the medium passing in the annular space does not form deposits that require mechanical cleaning of the outer surface of the heat exchange tubes.

Devices with welded twins (version 1) are designed for conditions when the environment of the pipe space also does not require mechanical cleaning of the inner surface of the heat exchange pipes.

Devices with removable twins (version 2) are most suitable for operation, causing the need for regular mechanical cleaning of the inner surface of the heat exchange tubes from contamination.

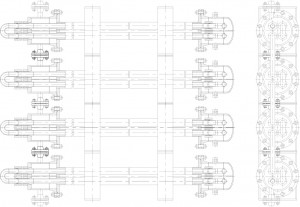

All types of devices can be arranged in sections from a different number of elements and installed on frames.

Пример компоновки элементов теплообменника труба в трубе однопоточного неразборного ТТОН в блок

Пример компоновки элементов теплообменника труба в трубе разборного малогабаритного ТТРМ в блок

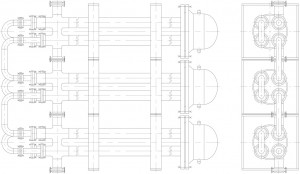

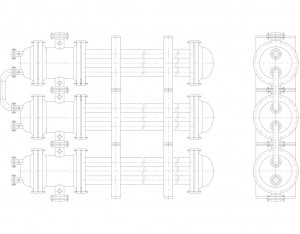

Пример компоновки элементов теплообменника труба в трубе однопоточного разборного ТТОР в блок

Пример компоновки элементов теплообменника труба в трубе многопоточного ТТМ в блок

Place an orderОсновные параметры теплообменных аппаратов «труба в трубе».

| Исполнение аппарата, обозначение НТД, код ОКП | Группа теплообменников | Диаметр труб, мм | Давление Ру, МПа | Длина труб, мм L | ||

| внутренних d | наружных D | в трубном пространстве | в межтрубном пространстве | |||

| Неразборные однопоточные малогабаритныеТУ 3612-014-00220302-99ОКП 36 1221, 36 1222 | ТТОН 25/57 | 25 | 57 | 6,3; 16,0 | 4,0; 10,0 | 1500-3000 |

| ТТОН 38/57 | 38 | |||||

| ТТОН 38/76 | 76 | 6,3 | 4,0 | |||

| ТТОН 38/89 | 89 | 3000, 4500 | ||||

| ТТОН 48/76 | 48 | 76 | 6,3; 10,0; 16,0 | 4,0; 6,3; 10,0 | 3000, 4500, 6000 | |

| ТТОН 48/89 | 89 | 10,0; 16,0 | 6,3; 10,0 | |||

| ТТОН 48/108 | 108 | 6,3; 10,0 | 4,0; 6,3 | |||

| ТТОН 57/89 | 57 | 89 | 10,0; 16,0 | 6,3; 10,0 | 4500, 6000 | |

| ТТОН 57/108 | 108 | 6,3; 10,0; 16,0 | 4,0; 6,3; 10,0 | |||

| ТТОН 89/133 | 89 | 133 | 1,6; 4,0; 6,3;10,0; 16,0 | 1,6; 4,0; 6,3; 10,0 | 6000, 9000 | |

| ТТОН 89/159 | 159 | |||||

| ТТОН 108/159 | 108 | |||||

| ТТОН 133/219 | 133 | 219 | 4,0; 10,0; 16,0 | 9000 | ||

| ТТОН 159/219 | 159 | 1,6; 4,0; 6,3; 10,0 | 1,6; 4,0; 6,3 | 6000, 9000 | ||

| Разборные однопоточныеТУ 3612-014-00220302-99ОКП 36 1221, 36 1222 | ТТРМ 25/57 | 25 | 57 | 6,3; 10,0; 16,0 | 1,6; 4,0; 6,3; 10,0 | 1500, 3000 |

| ТТРМ 38/57 | 38 | 10,0 | 1,6; 4,0 | |||

| ТТРМ 38/76 | 76 | 10,0; 16,0 | 1,6; 4,0; 10,0 | |||

| ТТРМ 38/89 | 89 | 6,3 | 1,6; 4,0 | 3000, 4500 | ||

| ТТРМ 48/76 | 48 | 76 | ||||

| ТТРМ 48/89 | 89 | 6,3; 10,0 | 1,6; 4,0; 6,3 | 3000, 4500, 6000 | ||

| ТТРМ 57/89 | 57 | 10,0 | 1,6; 4,0 | 4500, 6000 | ||

| ТТРМ 57/108 | 108 | 1,6; 4,0; 6,3 | ||||

| Разборные многопоточныеТУ 3612-014-00220302-99ОКП 36 1221, 36 1222 | ТТМ5 38/89 | 38 | 89 | 1,6; 4,0 | 1,6; 4,0 | 3000, 4500, 6000 |

| ТТМ5 48/89 | 48 | |||||

| ТТМ5 48/108 | 108 | |||||

| ТТМ5 57/108 | 57 | |||||

| ТТМ7 38/89 | 38 | 89 | 4500, 6000, 9000 | |||

| ТТМ7 48/89 | 48 | |||||

| ТТМ7 48/108 | 108 | |||||

| ТТМ7 57/108 | 57 | |||||

| ТТМ12 38/89 | 38 | 89 | 6000, 9000 | |||

| ТТМ12 48/89 | 48 | |||||

| ТТМ12 48/108 | 108 | |||||

| ТТМ12 57/108 | 57 | |||||

| ТТМ22 38/89 | 38 | 89 | ||||

| ТТМ22 48/89 | 48 | |||||

| ТТМ22 48/108 | 108 | |||||

| ТТМ22 57/108 | 57 | |||||

| ТТМ31 38/89 | 38 | 89 | ||||

| ТТМ31 48/89 | 48 | |||||

| Разборные однопоточныеТУ 3612-014-00220302-99ОКП 36 1221, 36 1222 | ТТОР 89/133 | 89 | 133 | 1,6; 4,0 | 1,6; 4,0 | 4500,6000, 9000 |

| ТТОР 89/159 | 159 | |||||

| ТТОР 108/159 | 108 | |||||

| ТТОР 133/219 | 133 | 219 | 6000,9000 | |||

| ТТОР 159/219 | 159 | |||||