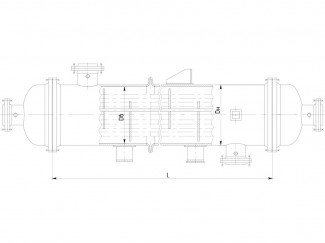

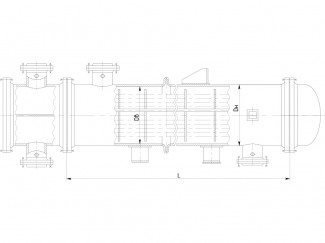

Shell-and-tube heat exchange units with fixed tube gratings and shell-and-tube heat exchangers with a temperature compensator on the casing

The devices are designed for heat exchange of liquid and gaseous media in technological processes of chemical, petrochemical, oil refining, oil, gas and other industries.

Heat exchangers are divided into:

- by purpose: for heat exchangers (T), refrigerators (X), condensers (K), evaporators (I) of types “H” and “K” and their modifications;

- by design: for devices with fixed tube sheets (type H), with a temperature compensator on the casing (type K);

- by location: on horizontal “G” (TNG, TKG, HNG, HKG, KNG, KKG) and vertical “B” (TNV, TKV, HNV, HKV, KNV, KKV, INV, IKV).

The cooling medium in refrigerators and condensers is water or other non-toxic, non-explosive and non-flammable liquid with a boiling point at a pressure of 0.07 MPa above 60 °C.

Evaporators are manufactured in two versions:

- version 1 – evaporators with liquid, gaseous, vapor-gas and vapor-liquid coolant (IN-1, IK-1);

- version 2 – evaporators with steam coolant (IN-2, IK-2).

Devices can be made single-element and multi-element.

Smooth (G) heat exchange tubes are used in the apparatuses.

The devices can be operated in macroclimatic regions with a temperate and tropical climate. Climatic version “U” and “T”, product category 1 according to GOST 15150-69.

The devices are designed for installation in geographical areas with seismicity less than 7 points according to the 12-point scale adopted in the Russian Federation.

The devices are designed for installation in geographical areas with seismicity less than 7 points according to the 12-point scale adopted in the Russian Federation.

The possibility of operation in areas with seismicity of 7 or more points is determined by the calculation for seismicity according to SNiP II-7-81, taking into account a specific size.

The main materials used in the manufacture of devices: carbon steel, stainless steel, brass.

In the case when the operated heat exchanger does not cope with its functions, or it is required to select an apparatus for designing a new technological scheme, SPA “SPETSNEFTEKHIMMASH” has the opportunity to carry out a heat engineering calculation and recommend the type of apparatus. The selection of devices is carried out on the basis of a questionnaire.

It is allowed to select devices by a design organization using this type of equipment, while this organization is responsible for the correct choice of devices.

When ordering devices, an order form is submitted.

Place an orderОсновные типы и технические характеристики теплообменных аппаратов

| Наименование, тип, ТУ, код ОКП | Диаметр кожуха, ммDH, DB | Длина труб, L мм | Сортамент труб, мм | Число ходов по трубам | Условное давление, МПа | Площадьповерхности теплообмена, м2 | |||

| в кожухе | в трубах | ||||||||

| Н | К | Н | К | 1,0 – 973 | |||||

| Теплообменники с неподвижными трубными решетками (ТН), с неподвижными трубными решеткам и температурным компенсатором на кожухе (ТК)ТУ 3612-024-00220302-02 ОКП 36 1211 | 159 | 1000, 1500, 2000, 3000 | 20×2, 25×2 | 1 | 1,6 – 4,0 | 1,6 | 1,6 – 4,0 | 1,6 | |

| 273 | |||||||||

| 325 | 1500, 2000, 3000,4000 | 1; 2 | |||||||

| 400 (426) | 2000, 3000, 4000, 6000 | ||||||||

| 600 (630) | 1; 2; 4 | ||||||||

| 800 | 1,0 – 4,0 | 1,0 – 1,6 | 1,0 – 4,0 | 1,0 – 1,6 | |||||

| 1000 | 3000, 4000 6000, 9000 | 0,6 – 2,5 | 0,6 – 1,6 | 0,6 – 2,5 | 0,6 – 1,6 | ||||

| 3000, 4000, 6000 | 4,0 | 4,0 | |||||||

| 1200 | 4000, 6000, 9000 | 0,6 – 2,5 | 0,6 – 2,5 | ||||||

| Холодильники с неподвижными трубными решетками (ХН), с неподвижными трубными решетками и температурным компенсатором на кожухе (ХК) ТУ 3612-024-00220302-02 ОКП 36 1211 | 159, 273 | 1500, 2000, 3000 | 25×2 | 1 | — | 1,6 | — | 0,6 | 1,5 – 787 |

| 325 | 1500, 2000, 3000, 4000 | 2 | |||||||

| 400 (426) | 2000, 3000,4000, 6000 | ||||||||

| 600 (630) | 2; 4 | 1,0 – 4,0 | 1,0 – 1,6 | 0,6 | |||||

| 800 | |||||||||

| 1000 | 3000, 4000, 6000, 9000 | 0,6 – 2,5 | 0,6 – 1,6 | ||||||

| 3000, 4000, 6000 | 4,0 | ||||||||

| 1200 | 4000, 6000, 9000 | 0,6 – 2,5 | |||||||

| Конденсаторы с неподвижными трубными решетками (КН), с неподвижными трубными решетками и температурным компенсатором на кожухе (КК) ТУ 3612-024-00220302-02 ОКП 36 1211 | 600 (630) | 3000, 4000,6000 | 25×2 | 2; 4; 6 | 1,0 – 2,5 | 1,0 – 1,6 | 0,6 | 0,6 | 45 – 706 |

| 800 | |||||||||

| 1000 | 0,6 – 2,5 | 0,6 – 1,6 | |||||||

| 1200 | 4000, 6000 | ||||||||

| 1400 | 6000 | ||||||||

| Испарители с неподвижными трубными решетками (ИН), с неподвижными трубными решетками и температурным компенсатором на кожухе (ИК) ТУ 3612-024-00220302-02 ОКП 36 1211 | 600 (630) | 2000, 3000,4000 | 25×2 | 1 | 1,0 – 4,0 | 1,0 – 1,6 | 0,6 – 1,0 | 0,6 – 1,0 | 40 – 490 |

| 800 | |||||||||

| 1000 | 0,6 – 4,0 | 0,6 – 1,6 | |||||||

| 1200 | 3000, 4000 | 0,6 – 2,5 | |||||||

| 1400 | |||||||||