Air cooling units

- pneumatic, manual or electric blinds;

- automatic fan blade controller;

- frequency converters;

- electric motors with reversed polarity.

-

Place an order

Place an orderAir heater, heat recovery unit

Teplohim JSC has mastered the production of new equipment, namely, the air heater T-321. It was manufactured for the construction of an ammonium nitrate granulation plant for the

-

Place an order

Place an orderWhat is an air cooler? It is a functional and reliable device that effectively provides heat exchange processes for a specific working environment. Bringing the substance to the

-

Place an order

Place an orderWire heat exchange intensifiers (turbulence stimulators)

Wire heat exchange intensifiers (turbulence stimulators) are inserts placed in the heat exchange pipes of the air cooling unit along the entire length of the pipes. Wire heat

-

Place an order

Place an orderLow-flow AVM air cooling devices

These units are designed for condensation and cooling of vaporous, gaseous and liquid media used in technological processes of oil refining, petrochemical and other related

-

Place an order

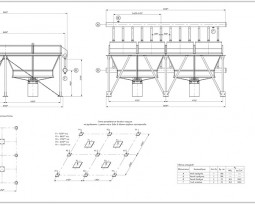

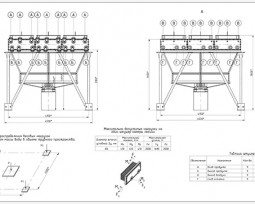

Place an orderAVG-KB (AVG-BM) block-modular air cooling units

These units are designed for condensation and cooling of vaporous, gaseous and liquid media in the technological processes of oil refining, petrochemical and related industries.

-

Place an order

Place an orderAir cooling units of block-modular type with recirculation of heated air

These units are designed for condensation and cooling of vaporous, gaseous and liquid media in the technological processes of oil refining, petrochemical and related industries.

-

Place an order

Place an orderThese units are designed for cooling viscous (with an output viscosity of up to 2 x 10-6 m²/s) products of oil refining, petrochemical and related industries. Type of climatic

-

Place an order

Place an orderThese units are designed for natural gas cooling in gas or related industries. The device consists of two heat exchange sections made up of bimetallic finned pipes. The sections

-

Place an order

Place an orderThese units are designed for cooling high-viscosity products with an output viscosity of more than 2 x 10-4 m²/s in the oil refining, petrochemical and related industries. Type

-

Place an order

Place an orderThese units are designed for cooling natural gas and condensation of liquid hydrocarbons. The unit consists of four heat exchange sections made up of finned bimetallic pipes.

Air coolers or classic heat exchangers?

As a rule, the cost of air coolers is higher than the cost of heat exchangers operating on the principle of water cooling. On the other hand, air cooling eliminates the problems of corrosion and contamination caused by the use of water. In addition, the possibility of mixing water with a process fluid requiring cooling is excluded in air-cooling units. It follows that the maintenance costs of air coolers are lower. In any case, the decision to use a specific heat exchanger is made individually for each situation.Production of air coolers for various industries

The production of such units has been established by the company Teplohim JSC. We produce air coolers of the following types:- low-threaded;

- block-modular type;

- zigzag;

- horizontal.

Features of the device air coolers

The unit consists of the following elements:- heat exchange sections that are installed on a common frame;

- fans responsible for pumping air flows through the device;

- fan drives.

Key benefits of air coolers

The demand and prevalence of air coolers is easily explained by a whole range of significant advantages of using such units:- Cost-effective energy consumption.

- An individual solution to the problems of your production.

- Relatively low specific metal consumption.

- Possibility of adjustments for exact observance of a specific regime.

- Possibility of designing devices with various configurations suitable for these operating conditions.

- The presence of a recirculation and heating system for air entering the sections of the apparatus, which ensures its stable operation in the cold period.

- Complete set with elements providing additional stability of work (blinds, electric motors, frequency converters).