Vacuum capacitors

Condensers are designed for condensing media under vacuum in the technological processes of petroleum, chemical, petrochemical, gas and other industries.

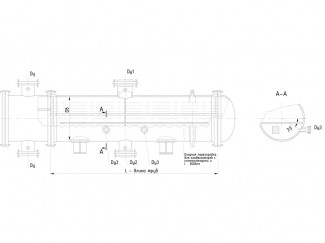

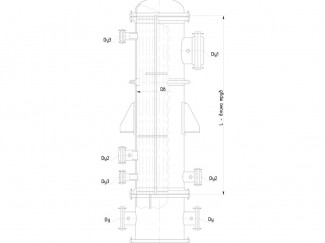

Vacuum condensers with fixed tube sheets of the KVN type, with fixed tube sheets and a temperature compensator on the casing of the KVK type are manufactured in two types: horizontal and vertical.

Depending on the design, horizontal condensers can be manufactured in four versions:

- Execution 1 – with a detachable distribution chamber, a flat cover and a casing with a diameter of 600-1200 mm with a length of heat exchange pipes of 3000 and 4000 mm;

- Execution 2 – with a detachable distribution chamber, a flat cover and a casing with a diameter of 800-1200 mm with a length of heat exchange pipes of 6000 mm;

- Execution 3 – with a split distribution chamber, elliptical cover and a casing with a diameter of 1400-2000 mm with a length of heat exchange pipes of 3000 and 4000 mm;

- Execution 4 – with a split distribution chamber, elliptical cover and a casing with a diameter of 1400-2000 mm with a length of heat exchange pipes of 6000 mm.

Vertical condensers with a casing diameter of 600-1200 mm are made with an offset tube bundle, with a casing diameter of 1400-2000 mm – with casing expansion in the steam inlet zone.

Depending on the design of distribution chambers, vertical condensers can be manufactured in two versions:

- Execution 1 – with a detachable distribution chamber, a flat cover and a casing with a diameter of 600-1200 mm;

- Execution 2 – with a detachable distribution chamber, elliptical cover and casing with a diameter of 1400-2000 mm.

The condensers use smooth (G) heat exchange tubes.

Capacitors can be operated in macroclimatic regions with temperate and tropical climates. Climatic version “U” and “T”, product category 1 according to GOST 15150-69.

Capacitors are designed for installation in geographical areas with seismic activity less than 7 points according to the 12-point scale adopted in the Russian Federation.

The main materials used in the manufacture of devices: carbon steel, stainless steel, brass.

When ordering devices, an order form TU 3612-007-00220302-99 must be submitted.

The order of devices with design changes must be made in accordance with the order form TU 3612-007-00220302-99.

Place an orderОсновные параметры конденсаторов вакуумных

| Наименование, тип, ТУ, код ОКП | Диаметр кожуха, DB, мм | Длина труб, L, мм | Сортамент труб, мм | Число ходов по трубам | Условное давление,* МПа,не более | Площадь поверхности теплообмена, м2 | |

| в кожухе | в трубах | ||||||

| мм. рт. ст. | МПа | ||||||

| Конденсаторы вакуумные горизонтальные с неподвижными трубными решетками (КВНГ), с неподвижными трубными решетками и температурным компенсатором на кожухе (КВКГ), ТУ 3612-007-00220302-99,ОКП 361211 | 600 | 3000; 4000 | 25×2 | 2, 4, 6 | вакуум до 5 | 0,6 | 32 ÷ 55 |

| 800 | 3000; 4000; 6000 | 70 ÷ 164 | |||||

| 1000 | 131 ÷ 294 | ||||||

| 1200 | 204 ÷ 449 | ||||||

| 1400 | 243 ÷ 531 | ||||||

| 1600 | 345 ÷ 742 | ||||||

| 1800 | 465 ÷ 990 | ||||||

| 2000 | 595 ÷ 1257 | ||||||

| Конденсаторы вакуумные вертикальные с неподвижными трубными решетками (КВНВ), с неподвижными трубными решетками и температурным компенсатором на кожухе (КВКВ), ТУ 3612-007-00220302-99,ОКП 361211 | 600 | 3000; 4000 | 4, 6 | 32 ÷ 47 | |||

| 800 | 3000; 4000; 6000 | 70 ÷ 149 | |||||

| 1000 | 131 ÷ 272 | ||||||

| 1200 | 204 ÷ 422 | ||||||

| 1400 | 4000; 6000 | 435 ÷ 669 | |||||

| 1600 | 620 ÷ 948 | ||||||

| 1800 | 6000 | 1190 ÷ 1210 | |||||

| 2000 | 1444 ÷ 1464 | ||||||

* Разрешается применять конденсаторы с диаметром кожуха 600÷1000 мм при давлении в кожухе до Ру=1,0 МПа и с диаметром кожуха 1200÷2000 мм при давлении до Ру=0,6 МПа